Building Fabric and Materials

Building Biology covers the interrelationships between humans and the built environment and attempts to improve our built ecology. This is both our impact on the external environment, but also how the internal environment, that we’ve created, affects our health.

The SBM 2015 guidelines are a three-page document of measurable targets that can be used to identify risks and target improvements tailored to the building type, venerability of its occupants and what’s achievable within the budget.

- Part A: Radiation, Light and Noise (9 Categories)

- Part B: Toxins, Pollutants and Climate (6 Categories)

- Part C: Fungi, Bacteria and allergens (4 Categories)

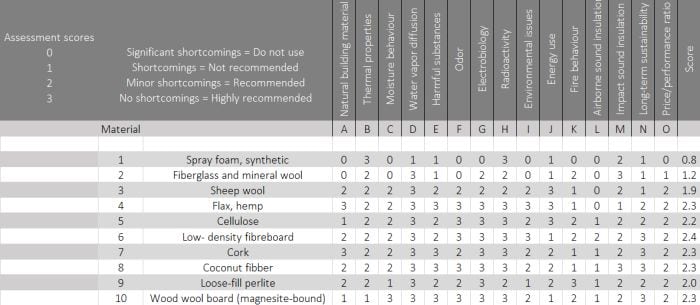

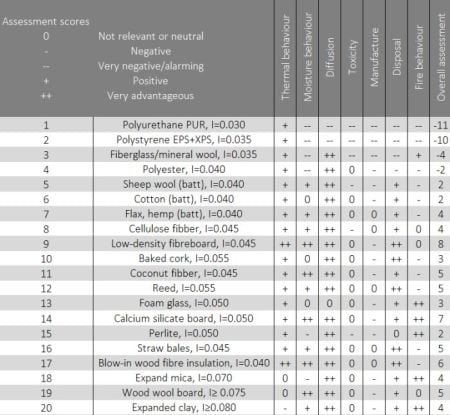

Choice of materials straddle all three parts of SBM 2015 and play a vital role in producing a healthy building. In fact, Building Biology champions the fabric first design process, aligning with the Passivhaus standard with an added appreciation within Building Biology as to the way fabric first design is achieved. Building biology endorses the use of materials with low embodied carbon, are inherently natural, toxin-free and materials that support our health rather than detract from it.

Building Biology Guiding Principles

Material selection is a major component of the Building Biology. This can be demonstrated in the recently updated 25 guiding principles, of which many relate to materials:

- Use materials with pleasant or neutral smell

- Use natural non-toxic materials with the least amount of radioactivity

- Strive for balance between thermal insulation and thermal mass

- Use humidity buffering materials

- Keep the moisture content of the new construction as low as possible

- Optimise room acoustics

- Promote regional building traditions and craftmanship

- Choose materials and life cycles with best environmental performance

The IBN design process and the SBM 2015 guidelines try to get design teams to look at Ecology, People and Economy holistically during the design and not in isolation at different stages within a project, where they can often be diluted to Carbon, H&S and Cost.

Indoor Air Quality (IAQ) is dependent on internal humidity regulation (as discussed in my first blog). Choosing the correct building fabric is key to achieving a balanced level of humidity, both in terms of thermal mass and moisture transportation.

Temperature and Thermal Mass

Building Biology principles also have a focus on the use of the building and the incorporation of thermal mass to regulate temperature and humidity swings. Typically, a dwelling should aim for 50% of the space elements to incorporate some thermal mass either in the structure or incorporated into the finishes. Over the diurnal cycle between 40-90mm (depth) of the thermal mass exposed to the room and ventilation will often be beneficial. It also takes a similar approach to Passivhaus in terms of passive improvement and comfort, where no surface shall be more than 40C temperature difference.

Humidity and Dust

This covers keys areas such as bacteria, metals, pollen of all shapes and sizes and levels of ingestion. Greater than 10µm breathing filters/collects these in the head and nose, between 10-2.5µm these typically filters/collects in the bronchia, less than 2.5µm reach the alveoli and enter your blood stream. Filtration via mechanical ventilation helps, for instance typical warehouse filtration (G4) removes 90% of dust greater than 1µm whereas healthcare (F9) removes 95% of particles greater than 0.4µm. However, fine heavy metals can still accumulate in the kidneys and liver over time from off gassing products such as timber treatments, fire retardants and paints.

Relative Humidity has a large bearing on dust. Greater than 60% humidity and bacteria, viruses, mites and asthma become more prevalent, below 40% humidity and respiratory infections, ozone and asthma also begin to rise. Additionally, below 40% electrostatic charge becomes more dominant in the movement and transportation of dust particles.

Therefore, when choosing materials, their effect on relative humidity should be a significant consideration.

Also, internal finishes can either unleash the properties of the constructions behind them, and their potential benefits, or seal them off creating an active vapour control layer. Diffusion open materials and finishes; typical lime, clay, or mineral paints (Sd Value of 0.02) are always promoted.

Internal Finishes and VOCs

Understanding internal finishes and their part to play in VOCs off gassing and dust propagation is important to measure the effects on the building’s occupants. However, SMB2015 also considers the health of those constructing the building, for example, being mindful not to specify items like lightweight concrete blocks. These have high fly ash content which can stay airborne for 3-4 days and be ingested into the lungs on site. Also, products with high glue contents should be avoided as they often contain formaldehyde or cyanide which can be carcinogenic/mutagenic/reprotoxic agents.

Volatile Organic Compounds (VOCs) are also a major consideration in Building Biology and a lot of this can be dictated by internal finishes, but also internal finishes can either unleash the properties of the constructions behind them, and their potential benefits, or seal them off creating an active vapour control layer. Diffusion-open materials and finishes such as typical lime, clay, or mineral paints (Sd Value of 0.02) are always promoted.

EN717-1:2004 covers formaldehyde off gas from timber products. Internal plywood can be particularly high in formaldehyde content. Under EN717, if the board doesn’t contain formaldehyde the product will automatically receive an EC1 (Emicode) rating. However, what they replace it with is normally a polyurethane glue producing isocyanates which are equally hazardous. They can cause skin irritations, mucous membrane and asthma, its affects, due to particulate size, are below the testable level and can only be picked up in blood or urine test for antibodies that are produces by the body following exposure.

Watch-it note: active VOC absorption products such as the 2 listed below. The Fermacell and KEIM MiNOx paints use Titanium Dioxides that were listed as a Carcinogen in 2017.

What are Healthy Materials?

So where can we find healthy building materials and internal finishes?

UK Standards governed by the HSE EH40/2005 only concern itself with legal thresholds that relate to a lethal dose and not what a healthy dose and exposure level would be.

The Green Guide (1996) is another reference point which is now integrated into BREEAM. However, their focus is predominantly on entire construction and not individual materials. Generally, these constructions are typically carbon weighed (22%) with only 9% relating to toxicity of materials. That toxicity is also on the external environment and not its effect on the internal environment, no VOC test is required, and it openly excludes its effects on humans directly.

Emicodes is a good source for VOC levels of internal finishes EC2, EC1, EC1plus, the REACH Database is a good source of information and products Safety Data Sheets (SDS), but only if deemed hazardous under EC1273/2008 otherwise it won’t show up on the document.

Fire retardants added to products are also a new and ever-changing market. For example Medite SMART PLY produce a red edged fire-retardant board, which has FSC accreditation, no formaldehyde content (replaced with 4-5% isocyanate glue; relatively low %), but with added eco-friendly water-based fire retardant. Because the retardant is below 1% content quantity within the product its properties don’t have to be declared. One possibility is the retardant is believed to be based on heavy metals (Zi) which if correct would not be the healthiest of products to include in your build. As well as boards, be wary about fire retardant (as well as glue) products mixed within insulation products.

All Building Biology asks is for designers to be aware of the risks and pick the best products available and/or affordable, if you don’t know what’s in it, don’t specify it.