In the late 90s and early 2000s, anyone who was anyone was converting a barn to a home. Modern farms with more acreage from aggregating smaller farms can centralise their operations making remote structures redundant. Also, modern agricultural machines can be significantly larger than the vintage counterparts, so they simply don’t fit in older barns. Combined with the desirability of a house set in the countryside, and we have supply of, and demand for barn conversions. Such has been the popularity of these buildings that there are not many traditional, stone barns still left that are appropriate for conversion. We have even noticed some pastiche new-build barn-style dwellings.

In our first collaborative blog, our friends at Make Group, who are contractors on ‘Westcombe Barn’, a Class Q dwelling, offer the contractor’s view, and have provided the lovely drawings that illustrate our ideas. To view them, click here

Post-war agricultural buildings are more often than not portal frame steel structures, with corrugated steel cladding. As traditional stone barns have become less available, grand designers looking for their country home are turning to steel buildings to convert. This blog discusses some ideas about how to convert a steel barn to great levels of efficiency and comfort. Some of the principles might even apply to new steel framed buildings.

Class Q is one of the ‘permitted development’ rights, and allows the conversion, in certain circumstances, of agricultural buildings into dwellings. In April 2018 the legislation was amended and now permits the creation of either:

- three larger homes totalling no more than 465m2;

- five smaller homes each no larger than 100m2;

- A combination, within a total of no more than five homes, of which no more than three may be larger homes

Many other articles and blogs address the matter of what is and is not permitted, and the purpose of this blog is to explore how to retrofit a structure in an energy efficient way.

Where to start?

So you’ve reached an agreement with your friendly farmer to buy one of his rusty old barns. How to set about turning this into a modern, energy efficient home? Actually, with any luck you will be reading this before you’ve committed to a building, because some barns are more suitable than others and the following may be worth bearing in mind when searching.

Typically, with a Class Q development, the existing structure must remain, and the external lines of the building must remain. This sets up an immediate question – how structurally sound is the existing building? If it is too poor to remediate, but you aren’t allowed to replace it, you’re in an expensive catch-22. A full structural survey early in the process may be a wise investment.

There are some key questions any such survey should aim to answer:

- What is the load bearing capacity of the ground and column foundations, and how much load is currently on them? How much more can they safely take?

- What is the capacity of the above ground steel with respect to wind loading, dead loads of walls and roofs, and the dead and live loads of possible new internal floors?

- Can either of the above capacities be improved to provide an adequate structure, e.g. by underpinning foundations, additional lateral steel work etc. What impact does this have on the budget?

These questions will have a bearing on the best strategies for creating an efficient thermal envelope and are laid out in our handy infographic flow chart.

Thermal Envelope

Depending on the outcome of the survey and decisions about strengthening the structure, there are two pairs of options, with two choices each. The first choice is whether to impose additional new loads on the existing structure (the insulation, internal finishes, new internal floors, services etc), or whether the existing structure takes little or no more than the existing arrangement, and the additional loads are borne on their own, structurally independent foundations.

Allied to this decision is whether to place the thermal envelope inside or outside the steel frame. It is of course very tempting to place the insulation and airtightness layer within the zone of the steels, but this is a thermal disaster. Steel conducts heat about 2000 times better than typical insulation materials, and arrangements where the steel crosses from the warm side to the cold side of the insulation are equivalent to simply leaving out wide strips of insulation. As well as losing significant amounts of heat and increasing energy bills and plant sizes, thermal bridges can lead to mould growth and surface condensation, and reduce thermal comfort.

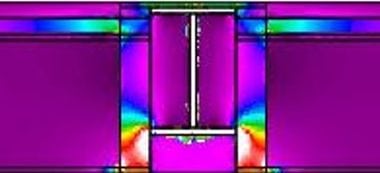

The following example was a draft detail (which we persuaded the team to avoid) on Westcombe Barn:

We calculated that the Ψ-value of this detail was 0.192W/m.K, and the wall U-value was 0.18 W/m2.K (Thick SIPs)

Based on a notional frame with columns at say 4m centres, for one storey height with a beam in the floor plane, the heat loss through SIPs alone would be 4 x 3 x 0.18 = 2.16 W/K. The additional heat loss through Steel Column = 2.5 x 0.192 = 0.48 W/K and, assuming the same psi-value, through Steel Beam = 4 x 0.192 = 0.77 W/K. The total heat loss through steel is therefore 1.25 W/K. the steel therefore increases the heat loss through the wall by over 50%!

On this project we ended up with a SIP panel on the outside of the frame, with a thinner extra layer of insulation fixed internally and bridged by the steels. Although this internal layer is somewhat compromised by thermal bridging, the impact is much reduced compared to the example above.

Separating the insulation zone from the steel zone also means that the airtightness barrier will be easier to install, and easy installation makes for better airtightness results. In theory, membranes can be taped to steels on either side, or wrapped around, but in both cases this leads to very difficult 3D details at either end of the steel, requiring challenging feats of origami with the AVCL that the most experienced airtightness practitioner will struggle to execute. A flat air barrier is a happy air barrier!

The lesson here is simple – for best thermal efficiency, locate all of your insulation either outside, or inside the steel frame.

This separation of structure and insulation will take up more space, but this is not the only drawback. Depending on how the existing barn is put together, a layer of insulation outside the frame will often push the external lines beyond the existing limits, which would necessitate a full planning application. Also bear in mind the Class Q rules on space, and the nature of agricultural barns compared to houses. Class Q limits the useable floor area to be developed. A canny architect, self-builder or developer might look at barns that seem a bit big against these rules, and use up some of the ‘unwanted’ space with nice thick insulation on the inside of the frame.

In the draft detail, you can see that internal columns will create a thermal bridge in all cases, and perimeter columns in the externally insulated cases. We sometimes get asked whether ground floors need less insulation because the ground is warmer in winter. The answer is yes, but not as much as you might think. We account for this effect by calculating a ‘ground reduction factor’, a multiplier which estimates the difference between the air temperature and ground temperature. This normally comes out at around 0.7 for a very well insulated floor, and 0.6 or a bit lower for a less well insulated slab on grade floor. Ventilated floors (e.g. beam and block) will be significantly higher. This means that the floor loses 30 – 40% less heat than it would if it were exposed to the air throughout the winter. The same is true of the thermal bridges, so in round terms, two thermal bridges in the floor are equivalent to three above ground.

Sometimes, schemes are proposed that use some but not all of the existing steel structure. In such cases, severe point thermal bridges can occur where the steel passes through the insulation zone, often at ridges and eaves. It is often impractical to introduce a thermal break such as Schoeck’s range of steel-to-steel thermal connectors, and the only other option is to demolish the offending parts of the frame. Of course, they might be an interesting design feature, but is such a feature worth the risk of mould and condensation? We’d say no.

Materials

There are many ways to insulate a building and some of the following points apply to not just Class Q conversions, but all buildings.

When wall thicknesses need to be kept to a minimum, many people opt for PIR. We would argue for embracing thick walls. Deep external reveals have a very useful function in providing shading, which is an important factor in reducing the risk of summer overheating, particularly when external shading devices would breach the Class Q rules. Splayed reveals are a design feature seldom seen in modern buildings, but very common on older ones. This simple trick increases the amount of light getting in and adds interest. Reveals can also be splayed externally.

Structural Insulation Panels (SIPs) can seem like an obvious choice, but they have drawbacks too. If being supported by the existing steel frame, it must be very plumb, true and square. The nature of barns is that often this won’t be the case, but you might get lucky. Even if the original frame was erected plumb, true and square, a minor accident with a tractor could have knocked it out, as Archers addicts will recall! Some SIP designs incorporate significant amounts of timber in the insulation zone at joints, increasing thermal bridging, and not all manufacturer provide the very thick panels necessary to get really low U-values necessary for some Passivhaus designs. Finally, there is some evidence to suggest that lightweight foam products (not just in SIPs) aren’t as good at resisting overheating as more dense products such as wood fibre, due to a factor called decrement delay – this is a measure of how quickly a change in temperature on the outside will change the temperature on the inside.

Timber framing is a huge topic in itself and there are dozens if not hundreds of different methods and details. In principle, this is as good a way as any for building an independent structure, if one is necessary, and the fine detail of the choice stick build, open panel, closed panel, TJI and so on will need to be weighed up for a particular project. One fairly universal factor will be that craning prefabricated panels inside the existing frame in will be very difficult if not impossible. It may be appropriate to use timber to enhance the existing structure if adopting structural strategy A.

There are many other possible solutions including masonry and ICF which we don’t have space to elaborate on here, but there is one last option we’d like to discuss: straw bales.

Straw bale building is a rustic tradition that isn’t for everyone, but there’s an undeniable appeal to the idea of using an agricultural product as the principle component in the conversion of an agricultural building. It’s a very self-builder-friendly method, the basic methods can be quickly learned and are quite forgiving, and pretty cheap. Within usual constraints, the bales are self-supporting, which could be useful in relation to the structural challenges of existing frames. Heavier windows may need a bit more structure, which is sometimes provided by building timber frames into the straw, or they could be hung off the steel, differential movement notwithstanding. Some care is needed in the design of foundations to protect the bales from moisture, but no more so than most other methods of construction. Placing bales inside the frame is the natural choice, so they can be thoroughly and easily protected by a rainscreen on the outside of the structure, while minimising thermal bridging and arguments with planners. Straw bales do take up a lot of room, but those splayed reveals are easy to create – with a chainsaw!

In conclusion…

Class Q is a planning route that can help solve a key problem for grand designers (getting a site and getting planning), but presents a plethora of other, more technical design problems. An efficient, comfortable building can almost always be achieved, but it can take some strategic planning, clever design and bold decisions to get there.

We’d be very happy to talk through your project with you. Contact us here